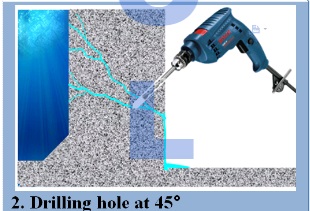

Drill holes at approximately 150 mm intervals along the side of the crack or joint, at 30⁰ to 45º angle to intersect with the path of the crack or joint. The depth of holes will depend on the size of the crack or seriousness of leakage.

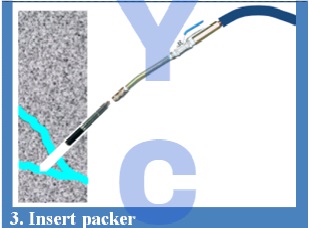

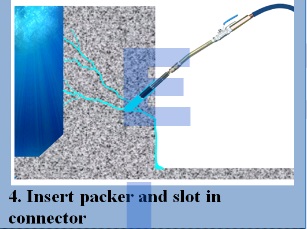

Wash with pipe water or pressurized air to clean any residue in hole. Insert and tighten the mechanical packers into the hole.

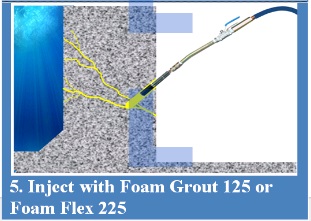

Connect Kühlzer XR-Series grouting machine and commence injection using the pre-determined material, ensuring that the crack is first sealed initially at stage (1). The material must be visible during the initial set stage where expanded foam can be seen. Return to previously injected packers and re-inject to ensure that the material is completely filled in stage (2).

In the event of grouting vertical cracks or joints, commence grouting from the bottom. In horizontal cracks or joint, begin grouting from either side. Repeat the above stages.

Best to allow grout material to cure for 24 hours before removing all the packers. Visible exposed solidified grout can be removed with scrapper or machine wire brush. Plug all drilled holes with a suitable mortar.

It is recommended to flush the machine with D-Solv 100 solvent and D-Lub 50 lubricant or non-flammable solvents before and after used.

Kühlzer XR-Series grouting machine is intended for experienced personnel or professional. Inexperience in handling the pump may cause damage or clog.

Please refer to our MSDS or call our Technical Department for any further engineering and safety consultation needed.